Zero Valent Iron (ZVI) – is a reductant used in the treatment of organic and inorganic contaminants found in soil and groundwater. Highly reactive micro-scale iron powder and granules for in situ chemical reduction of chlorinated solvents, metals, nitrates, nitroaromatic compounds, and certain dyes, among other contaminants of concern. ZVI is applied to soils and groundwater within source areas, permeable reactive zones/barriers, and other soil and groundwater remediation applications. CERES offers the best selection of highly reactive ZVI products to match up with the soil and hydrogeologic conditions as well as preferred injection approach. ZVI is a common component of BioGeoChemical Reduction approaches and is included in CERES BioGeochemical Reduction (BGCR).

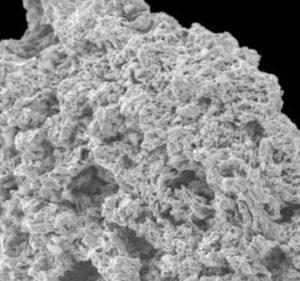

CERES Zero Valent Iron (ZVI) powder is produced by different manufacturing processes including reduced iron (i.e. Sponge Iron), hydrometallurgy, water atomization or carbonyl production methods (NOTE: CERES DOES NOT use scrap iron for our ZVI!). CERES ZVI is available at up to 99.5% Fe content and thousands of tons are produced annually with just-in-time manufacturing to ensure no appreciable surface oxides are present. Each manufacturing method produces ZVI of different iron content, reactivity and hydrogen production to meet our clients project specific requirements. Yes, we are engineering to order your ZVI. Who else does that?!

ZVI is one of the most effective and reliable remediation technologies, proven over decades to achieve successful in situ chemical reduction (ISCR) of many target contaminants. CERES has supported many clients with ZVI for ISCR projects around the world for many years with great success and proud to say that customer goals are being achieved one project after the other!

Would you like a quote for your project or a sample of one of our zero valent iron products? We can help –

Physical Properties

Form: Fine Powder to Aggregate

Density: 1.7-3.6 g/cm3

Molar Mass: 55.85

Odor: Odorless

Solubility in Water: Insoluble

Color: Grey

Vapor Pressure: N/A

| Material | % Composition |

|---|---|

| Iron | up to 99.5% |

| Carbon | less than 3.0% |

| Silicon | less than 2.5% |

| Manganese | less than 0.8% |

| Nickel | less than 0.20% |

| Sulphur | less than 0.15% |

| Phosphorous | less than 0.15% |

| SIZE | DISTRIBUTION % |

| 125-210 micron | 30-45% |

| 88-125 micron | 40-55% |

| 44-88 micron | 15-20% |

| SIZE OPTIONS | REFERENCE ID |

| 4 micron (D50=4µm, 2-7µm) | UF4- Ultra Fine 4 micron |

| 15 micron (D50=15µm; 5-30µm) | UF15- Ultra Fine 15 micron |

| <45 micron | micro 325 |

| 20-88 micron | micro 200 |

| 74-210 micron | standard micro 100 |

| 74-425 micron | F 1 |

| 125-425 micron | F 2 |

| 100-2,000 micron | Sponge PRB |

| 100-2,000 micron | PRB Blend |

ZVI specifically designed for open trench permeable reactive barriers (PRBs). C.E.R.E.S. offers a standard Sponge Iron ZVI PRB mix with a range from 100-2,000 microns with iron content up to 99%, very high reactivity, no appreciable surface oxides. However that can be modified to increase or decrease fines or coarse range. We can discuss and provide you technical support in the design of your PRB.

C.E.R.E.S. also offers a more customizable PRB Blend ZVI produced by combining sponge iron with atomized iron with iron content up to 99%, very high reactivity, no appreciable surface oxides. This blend can be modified to satisfy site specific size distributions for your design objectives.

Remember, no rusted scrap iron here! Don’t accept that level of quality. You have one chance to install the most reactive and longest performing PRB to achieve your goals and get the best results. Let C.E.R.E.S. support your ZVI needs.

| Arsenic (As) |

| Hexavalent Chromium (CrVl) |

| Cadmium (Cd) |

| Nickel (Ni) |

| Selenium (Se) |

| Chlorinated Solvents |

| Carbon-Tetrachloride |

| Energetics like TNT, DNT, RDS, HMX and Perchlorate |

| Technetium |

| Pesticides |

| Nitrate and Sulfate |

| Polychlorinated biphenyls (PCBs) |

2024 © CERES Remediation Products. All Rights Reserved.